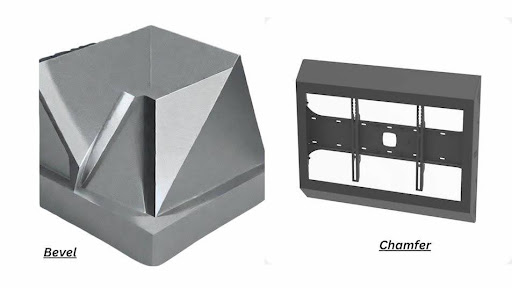

CNC machining leaves edges sharp with burrs in machined parts, which need to be further machined or finished to achieve the desired accuracy, functionality, safety, and aesthetic appeal. Beveling and chamfering are the two key techniques to finish the sharp edges. Beveling refers to cutting or shaping the edge of a material at an angle other than 90 degrees. In contrast, chamfering means finishing a flat and angled surface at the edge or corner of a workpiece, usually at a 45-degree angle.

Let’s discuss Bevel Vs Chamfer with their definition, process of making them, and how they help in further joining, fitting, finishing, and other secondary operations.

What is meant by a Bevel Edge?

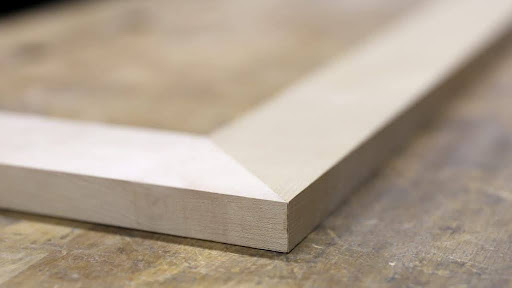

The bevel edge meaning refers to the edge of the part that is cut at a suitable angle, creating a slope to the surface plane. The cutting angle can be customized depending on needs. The reason for edge beveling is not only to enhance safety and decorative purposes, but also to prepare the surface for welding and other joining processes.

Bevel edges

You might have seen this kind of bevelled edges on the decorative frames, where it helps to join individual sides and also gives an aesthetically pleasing look. Some other notable examples of bevel edges parts & products are cutting tool edges, valve seats, knife blades, and teeth in some gear types.

You can choose a suitable bevel machining tool based on the desired beveled angle. They are available in 15°, 30°, 45°, 60°, etc.

What is Meant by a Chamfered Edge?

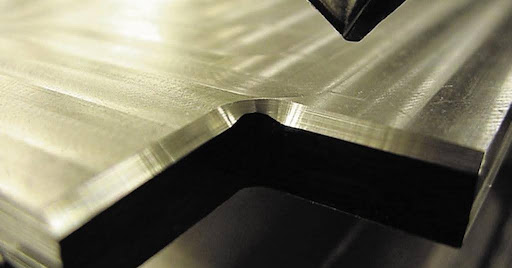

Chamfer machining involves cutting the straight edges at a 45° angle relative to one of the adjoining surfaces. So, the chamfered definition refers to a flat transition surface made at 45° between two adjoining surfaces. These small features on the edges remove the sharpness, making it easier to handle and also serving an aesthetic purpose in some cases.

Chamfered edge

Chamfered edge

CNC chamfering is also used to form a chamfered edge, removing the burrs and sharpness of hole end. This makes it easy to adjust bolt head, pins, or rings. Furthermore, chamfers are also used for parts assembly, fittings, and to counter the stress concentration on the edges.

Tools like counter sink bit, indexable chamfer cutter, internal chamfered hole cutter are used in cutting chamfers.

What Sets Bevels Apart from Chamfers?

Bevel vs chamfer

Bevel vs chamfer

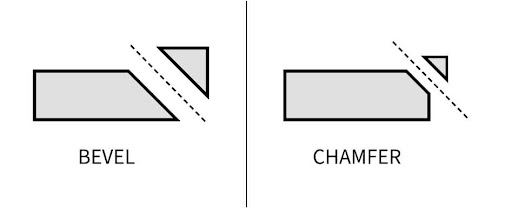

You can understand this way: “ all chamfers are bevels, but not all bevels are chamfers”. So, the angle at which the straight is cut sets them apart. For chamfer, it is always 45°, whereas bevels are flexible in this cutting angle. Moreover, the bevels provide a more gradual transition compared to chamfers.

The visual distinction is that chamfered edges look flatter and beveled edges involve more slope geometry. Furthermore, CNC Machining Services also treats chamfers and bevels differently. The CAM toolpath for beveling is more complex and taken as specialized operations for edge braking, but the chamfering tool path is made as simple edge finishing rather than a full-profile feature.

Discussing these two different features, one key common thing to understand is that both of them can be machined with different types of machining, including CNC Milling, turning, and turn-milling processes. Which one is the best CNC machining depends on the size, geometry, and compatibility of the design.

Bevel Vs Chamfer: Key Differences

It is important to understand the differences between bevel and chamfer before deciding which serves your edge treatment needs effectively. They have differences in their geometry advantages, limitations, purposes, and difficulties in machining them.

The table below shows the objective differentiation.

| Criteria | Bevel | Chamfer |

| Geometry | Sloped edge between two surfaces and vary the beveling angle. | Flat and straight edge between two adjoining surfaces commonly at 45°. |

| Advantages | Flexible angles, distinct aesthetics, and best for weld joining. | Simple geometry removes sharp edges, improves assembly fit and safety. |

| Limitations | Stress concentration at edges, requires precise alignment, and high material removal. | No angle flexibility and less visually distinctive. |

| Application Examples | Structural components, welded joints, decorative edges, gear teeth, pipe ends, etc. | Mechanical parts, electronic housings, fastener seat, furniture edges, and architectural trim. |

| Machining Complexity | High as it requires specialized tools or multiple passes. | Relatively simple, as standard mills, countersink cutters, or chamfering tools can perform this. |

| Cost | Higher due to specialized tools and longer machining time. | Lower because machining is simpler and faster. |

How to Choose Between Bevel and Chamfer?

Choosing between chamfer and bevel depends on different criteria like purpose, joining requirements, and desired aesthetic. Beveling meaning refers to a particular slope angle that connects two planes, whereas a chamfer serves the primary purpose of promoting safety by reducing sharp edges.

When to Use Bevel?

- To convert sharp edges to improve safety.

- For aesthetic purposes to enhance the appearance of the object.

- To create a larger bonding surface for operations such as welding or joining.

- The sloped profile of the bevel aids in efficient power transfer by reducing the friction.

When to Use Chamfer?

- A chamfer serves to create a lead, which is a guide surface that helps to insert mating parts and prevents misalignment or jamming.

- Chamfer helps to create controlled lead, while a bevel is widely used for decorative purposes, as it is not precise enough for guiding parts.

- For stress distribution, as it allows the load to distribute gradually along the surface rather than concentrating at a sharp edge.

Conclusion

Understanding the bevel vs chamfer differences helps you to choose the optimal option in your design. While beveling is preferred to give aesthetic appeal to the manufactured items, safety concerns are addressed efficiently by chamfering. Bevelling is used for load distribution while creating a large bonding area for joining purposes. Chamfering is generally easier and a standard machining procedure with minimum removal of material, and preferred in creating guiding parts for alignment.

If you are still confused which one to use, reach out to an expert in machining complex designs, like ProleanTech. This way, you can send your design and get help to select the best and cost-effective option based on your requirements.

FAQs

What is a chamfered edge?

The chamfered edge is a flat transitional surface made at 45° between two adjoining surfaces of the workpiece.

What are beveled edges?

Beveled edges are the sloped transitional surfaces between surfaces, typically at angles less than 90°. The common angles are 30°, 37.5°, and 60°.

Are chamfers always 45 degrees?

Although 45 °chamfers are the most common industrial practice, they can be cut in other angles than 45 °based on requirements. But, they are called bevels if cut in significantly more or less than°.

What is a rounded bevel called?

A rounded bevel is called “round over or radius edge,” which involves a curve along the transition between two planes of the workpiece.

What is the purpose of a beveled edge?

Beveled edges are cut at suitable angles to treat sharp edges for joining, fitting, welding, and aesthetics.