In the rapidly evolving world of manufacturing, laser welding has emerged as a game-changing technology that offers unmatched precision, speed, and versatility. Whether you are producing automotive components, medical instruments, or high-tech electronic parts, choosing the right laser welding solution can significantly impact your product quality and operational efficiency. This article explores the key benefits of laser welding, the factors to consider when selecting a machine, and a practical look at costs to help you make an informed investment.

What Makes Laser Welding Stand Out?

Laser welding uses a concentrated beam of light to melt and fuse materials together. Unlike traditional welding methods, it delivers minimal thermal distortion, high repeatability, and excellent control, making it ideal for both complex geometries and delicate parts.

One of the main advantages of investing in a high-quality laser welding machine is the consistent weld quality you can achieve even in high-volume production environments. Precision control of the laser energy ensures fine weld seams and reduces the need for post-weld finishing, ultimately saving time and cost.

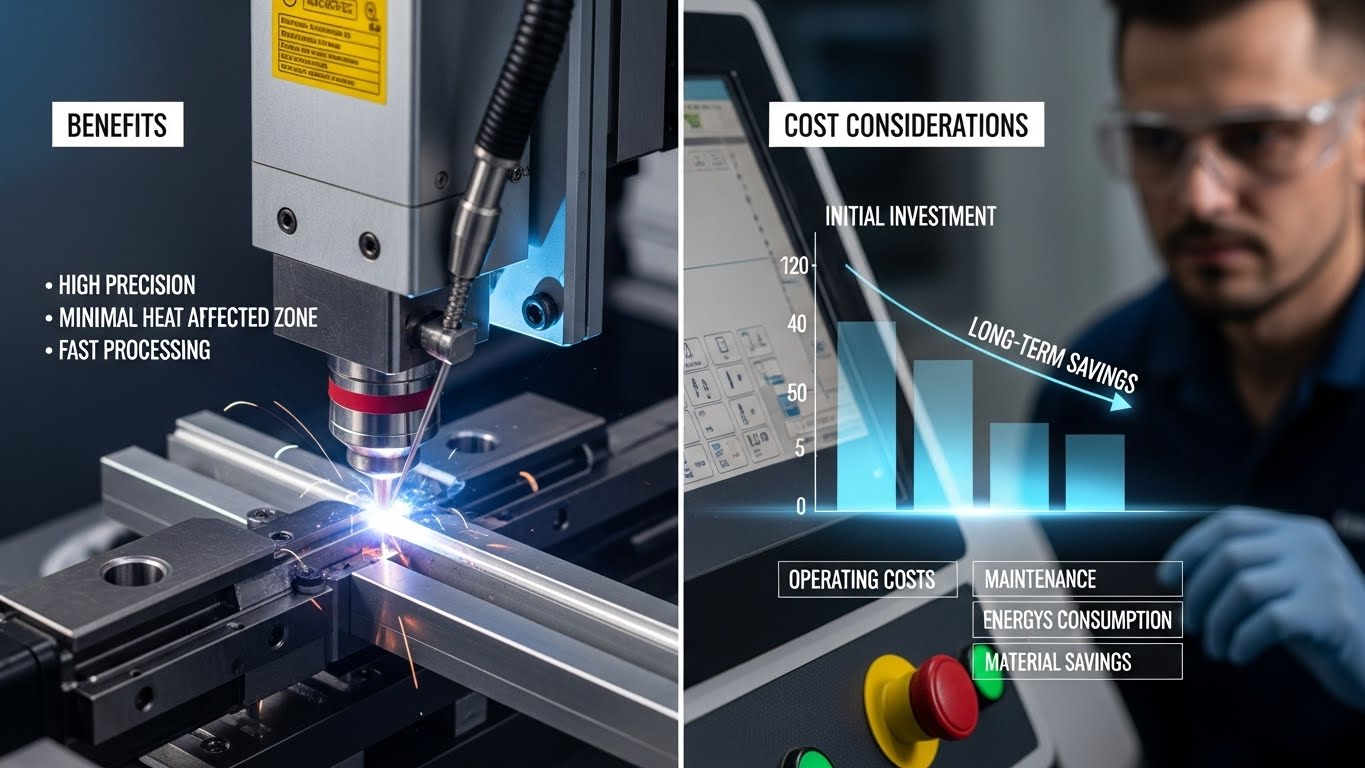

Key Benefits of Laser Welding Machines

1. Precision and Repeatability

Laser welding machines offer exceptional precision thanks to focused energy delivery. This ensures clean, strong welds with minimal need for rework. Industries such as aerospace and electronics benefit greatly from this capability, as even tiny misalignments can lead to costly defects.

2. Reduced Thermal Distortion

Traditional welding methods often produce excessive heat, which can warp or deform parts. In contrast, laser welding concentrates heat just where it’s needed, significantly reducing heat-affected zones and protecting sensitive components.

3. Versatility Across Materials

Laser welding is compatible with a wide range of metals, including stainless steel, aluminum, copper alloys, and more. This versatility makes it suitable for many sectors, from automotive to medical device manufacturing.

4. Faster Production and Automation Integration

Laser welding systems can be easily integrated with automation, including robotic arms and conveyor systems, allowing manufacturers to scale production with minimal manual intervention. Faster cycle times and automation reduce labor dependency and increase throughput.

Cost Considerations: What You Need to Know

While the performance advantages are clear, laser welding machines represent a significant investment. Understanding laser welder cost dynamics is essential before deciding on your purchase. For a detailed and up-to-date breakdown of pricing factors and expected expenses, refer to our in-depth analysis: laser welder cost.

Several elements influence the overall cost of a laser welding system:

1. Laser Source Type

Different laser sources—such as fiber, CO₂, and disk lasers—offer varying performance traits and price points. Fiber lasers, for example, are highly efficient, require less maintenance, and are often preferred for metal welding, but they may cost more upfront than basic CO₂ systems.

2. Power and Capability

Higher power lasers can weld thicker materials and operate at faster speeds, but they come with higher price tags. Evaluating your production requirements carefully will help you select a machine with the right balance of capability and cost.

3. Automation and Accessories

Adding automation features such as robotic integration, vision systems, or specialized fixturing can increase your initial investment. However, these enhancements often lead to significant productivity gains and long-term return on investment (ROI).

4. Maintenance and Service

Consider long-term maintenance when assessing cost. A well-engineered laser welding machine backed by strong manufacturer support can reduce downtime and service costs over its lifecycle.

How to Choose the Right System

Selecting the right laser welding system should begin with a thorough analysis of your applications and production goals. Ask these guiding questions:

- What materials and thicknesses will I be welding?

- What tolerances and precision levels are required?

- Will I integrate the machine with automation?

- What is my expected production volume?

Partnering with a reputable laser welding machine manufacturer ensures access not only to quality equipment but also to valuable consultation during the selection and implementation stages.

Conclusion

Laser welding represents a powerful, future-proof investment for modern manufacturing operations. Its precision, speed, and adaptability make it a preferred choice across industries seeking high quality and efficiency. By understanding both the benefits and the cost factors involved—especially the laser welder cost drivers—you can select a system that supports your long-term production strategy while maximizing ROI.

If you are ready to explore options or need help identifying the best solution for your needs, getting expert guidance from experienced laser system suppliers is a smart next step.